Automation Solutions

MATERIALS HANDLING EQUIPMENT

With an experienced team comprised of Mechanical, Electrical, and Software engineers, combined with a state of the art fabrication facility in Somersby, NSW, Crossmuller has the ability to provide various materials handling solutions to the manufacturing industry.

Developed initially for in-house requirements, our equipment has been developed by a manufacturer, for a manufacturer, with maintenance and efficiency as key design inputs.

Material Handling Equipment can be supplied to suit individual panels, packs, or bulk materials, including ancillary devices such as accumulators, stacking machines, turnover devices, or silos and delivery bins.

Equipment examples:

- Panel Conveyors

- Panel Stacking Devices

- Panel Buffering Devices

- Stack/Pack Conveyors

- Pallet Conveyors

- Pack and Panel Shuttles

- Stacking Devices

- Turnover Devices

- Bulk Material Handling

AUTOMATED WAREHOUSE SYSTEMS

Crossmuller has implemented a wide variety of Automated Storage systems both internally, and for external clients. The systems we implement are designed to store, sort, batch, and pick materials for maximum efficiency, and can be implemented in various sections of a plant to provide;

- Improved raw material storage and machine feeding/batching

- Sorting and picking systems for assembly/packaging lines

- End of Line storage for dispatch

- AGV integration

- Or a combination of these to suit

ROBOTIC SOLUTIONS

Over the years, Crossmuller has developed a highly capable robotics team to design and implement various innovative processing solutions. Previous solutions include;

- Automated machine tending

- Pick and Place robotics

- Robotic storage and sortation cells

- Robotic palletising

- Welding cells

Crossmuller engineers have the experience and expertise to develop customised robotic solutions, with in-house simulation capability and prototyping facilities.

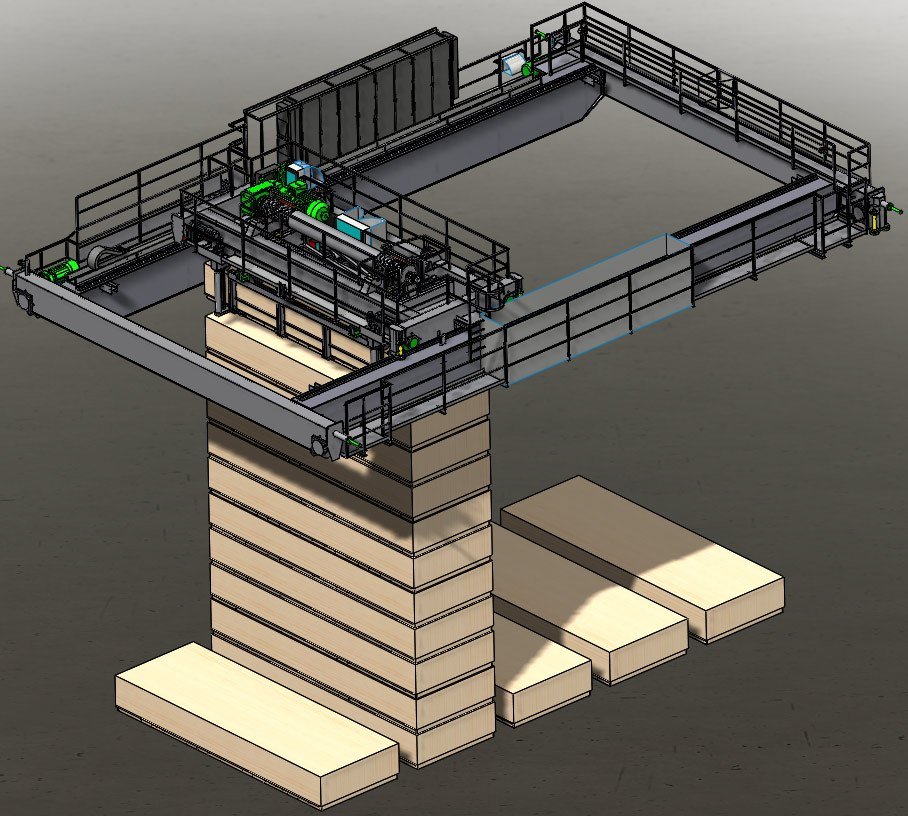

Our flagship solution for the panel industry, the Vertical Store is a panel management system that allows for storage of up to 2000 parts, with the ability to retrieve and outfeed these parts in the order specified by the downstream requirements. The Vertical Store provides an important buffer between processing cells in a plant, allowing each to be optimised for efficiency independently.

INTEGRATED SAFETY

Safety is an important consideration in any industry, especially manufacturing. Crossmuller is passionate about making Australian manufacturing safer, and this is a key component of any of our designs and installations. Our approach to safety is highlighted by our motto - "Safe by choice, not by chance".

Crossmuller can provide engineers to help improve safety at any level; from a small machine cell to a full, site wide Functional Safety Lifecycle implementation. Internally, we implement safety to AS61508 and can assist in implementing the same for our clients. Our TUV certified engineers can also conduct system validation so that you can be confident your plant poses minimal risk to staff.

Our safety guarding is manufactured in Australia, to Australian standards.