The project was completed and coincided with a production shutdown in January 2016.

The project was primarily a risk management exercise aiming to remove components which are difficult to replace should a failure occur, to migrate away from stand-alone SCADA systems and to further the use of an existing centralised VMware architecture.

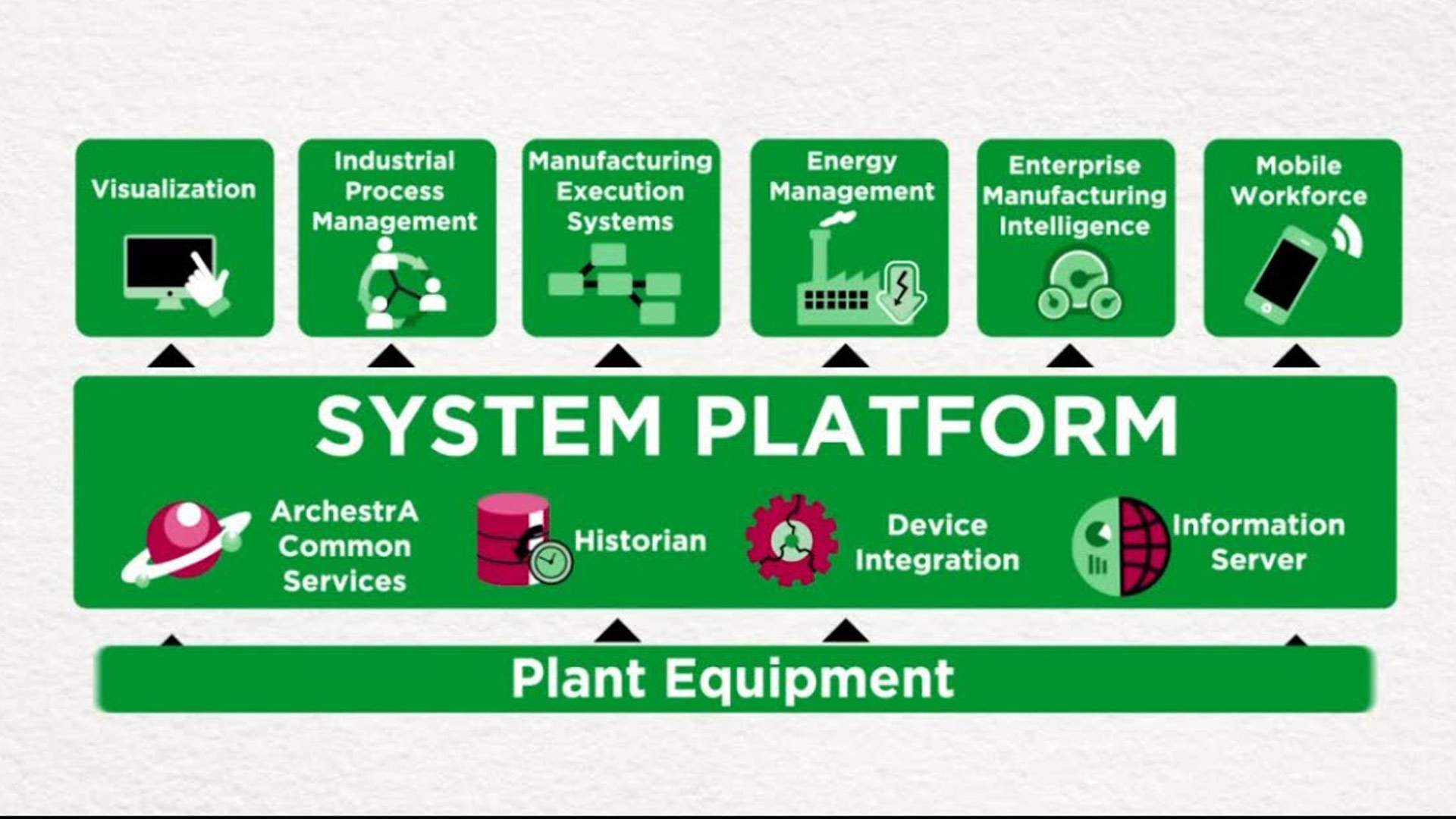

The upgrade made use of the Allen-Bradley PLC5 to ControlLogix I/O Wiring Conversion System to give the customer an extremely quick change-over to the latest in Allen-Bradley PLC Processors, and the SCADA components were migrated into the existing site Wonderware System Platform Environment. This provides many benefits to the plant including centralised development and management of the application, access to a world class Historian solution, and in the newer versions of System Platform inclusion of the new Wonderware Recipe Manager Plus.

But there is always a catch…

The site’s existing Wonderware System Platform Environment was of an older version and not compatible with the brand new Wonderware Recipe Manager Plus. Crossmuller provided a plan to not just simply install a new version of System Platform ‘over the top’, but to create a whole new environment and migrate the existing application content into the new system beside the application content coming from the PLC5/CITECT upgrade.

This approach gave the customer a number of benefits including:

- Upgrade to latest Microsoft Windows Server and Microsoft SQL Server Versions

- Alignment to Server and Control System Standards being rolled out throughout the organisation

The (virtual) servers were all built by the customer’s IT department ahead of time, and handed over to Crossmuller for Wonderware installation and configuration. The existing application content was migrated and tested offline as much as possible. Then during a planned weekend production shutdown back in September 2015, the existing system was taken offline and the new system was brought online. After further testing and with the aid of site Production and IT staff, the new system was signed off as ready for Production 32 hours later. Crossmuller provided onsite support for an incident free production start-up on Sunday night, provided training throughout Monday, and was on a 4pm flight home that same day.

The new system (PLC5/CITECT) content being developed offline will be imported into the new Wonderware System Platform 2014 R2 Environment just prior to the January shutdown, when the entire system will go-live.

This migration formed but one stage in a larger roadmap of changes being made to the customer’s control system. Making a conscious shift away from Stand-Alone InTouch Applications with direct communication to DA Servers, and moving towards a Wonderware System Platform centric model. When complete, this will give the system great flexibility, scalability and manageability with centralised configuration, development, and backups.