For Crossmuller working as a systems integrator on MES systems, we often focus on delivery of a technical solution and forget that for many of our customers, the transformational change involved in digitising their operations can be quite daunting. The culture of businesses and the subsequent journey followed in achieving real returns from an MES implementation will invariably be different for each.

The MES journey should always start with knowledge of what you have, and where you want to go. Taking the time to understand your current systems and defining a systems blueprint of what the end state is envisioned to be, enables the business to map the way forward on how to grow your MES capability in a manageable way.

Full blown MES solutions are complicated by nature. They need to interface to various systems from plant floor to ERP, they need to contextualise data, execute tasks and provide timely and insightful information to help the business meet production targets and continually improve. Achieving this is not a small task by any means, but this complexity should not be a deterrent to a business to embark on this journey as a good MES is usually built in stages using an agile approach where each function added provides incremental value to the customer and sets the building blocks in place for the next set of functionality to be added. Hence, companies that takes an incremental approach tend to have a better user experience, although it may take them longer to reach the final state.

Entry into the MES world tends to vary from business to business based on their position on the operations maturity curve. For many, it starts out as a data historian as a means to get better visibility into their operations and to be able to generate reports and dashboards that provide information in real-time that normally would have taken a day to generate and would not be available until well after production is complete. For others a bit further along, it could be a downtime classification and/or OEE system that will allow the business to identify bottlenecks and recurring issues to drive targeted improvement initiatives. These initial engagements mark the first foray into digitising operations data and getting wider visibility into the plant floor.

An MES is bigger than just the technology involved, it requires the business and their integration partner to focus on wider business aspects if they expect the system to be a success.

- Business Processes. Moving from a manual system to automated or digitised systems, the business need to ensure that all tasks that are being performed manually are clearly defined and will be catered for by the new system, however to truly drive returns, companies should attempt think out of the box about the potential for more fundamental transformations to their processes that the new technology can enable.

- People. MES systems often require changes to how operations staff perform their day to day tasks. This change should never be underestimated as the adoption of the system by people within the organisation will ultimately determine its success and usefulness to the business.

- IT/OT. We are finally seeing a concerted effort in businesses to narrow the gap between Information Technology and Operational Technology. When implementing MES solutions business should look at how these systems will fit into their current ITIL structures to ensure efficient operation and management of operating systems, virus and application software updates as well as the underlying infrastructure.

- Change. MES systems usually work in environments where there is continual change as a business adapts to the market and the requirements of their customers. A good MES should assist businesses in being flexible in their operations rather than locking them in to current ways of doing business. Understanding the evolving landscape of an organisation will help the business in selecting a MES that is most suitable to their environment.

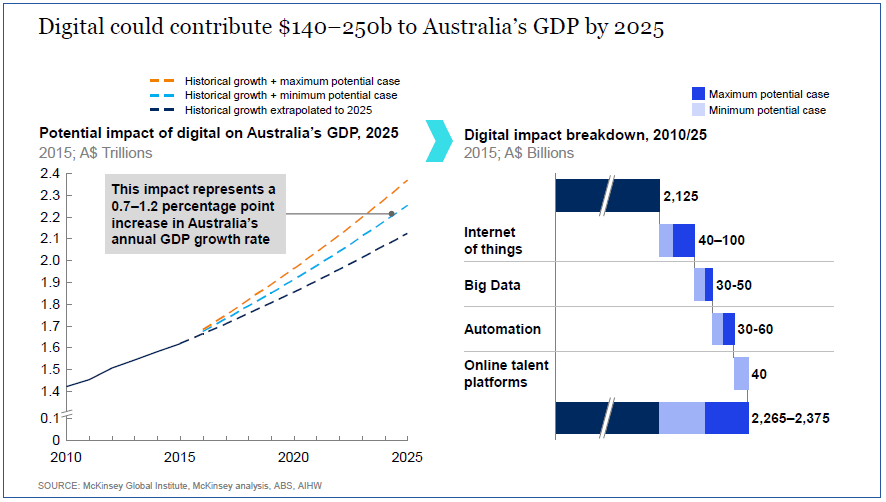

Any business that has started the journey will have an appreciation of the commitment a business makes when setting out implementing MES, however the prize is large. McKinsey’s “Digital Australia” report shows that the productivity of Australian Manufacturing is lagging up to 60% behind the most productive OECD nations and states that “Digitisation could contribute between $A140 billion and $A250 billion to Australia’s GDP by 2025 based on currently available technology alone.

Setting clear goals and following a phased approach allows a business to adapt and improve as they digitise their operations.

Crossmuller has over 20 years of experience working closely with Australian manufacturing businesses across multiple industries. If you’d like to speak to someone about how to start your digital journey, please contact us – we’d love to share some of our experience.