In the System Platform, InTouch and Historian landscape, participants are introduced to the key elements of the applications, which include connectivity to your preferred PLC to enable you to see how the system works seamlessly together.

These sessions have been particularly successful with both the trades and engineering teams on sites. The training will enable you to better understand the way Wonderware’s solution differentiates itself from other offerings, by utilising key object orientated configurations in a traditional tag based environment. This provides users with reusable and scalable solutions which add real value in future projects.

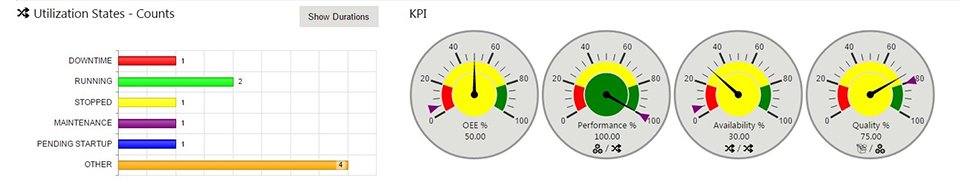

The MES training offered has a number of flavours, depending on requirements. The 4 foundational MES areas of Performance, Operations, Quality and Workflow can be covered at a very basic level, or the training can be targeted to one particular module. If your firm is looking to introduce any type of process improvement project in the coming year, Wonderware’s Performance Application (OEE and Downtime system), provides a paperless solution to enable customers to understand today’s line benchmarks, as well as identify bottlenecks and measure improvements, as they are introduced.

Please contact the team at Crossmuller (contact@crossmuller.com.au) if you would like us to run Wonderware Training in your organisation.