The obvious advantage of using the iPad was that they could walk right up to a piece of equipment and control it without the need to relay instructions back to an operator at the operator terminal.

The iPad uses a remote desktop application to connect to terminal services where the InTouch application is hosted so there is a zero footprint on the device. This also means that any device whether it be an Android powered device or a tablet can be used.

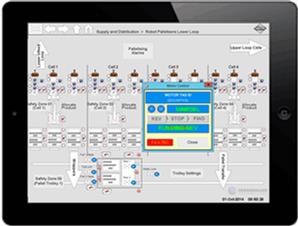

Navigation buttons are within easy reach of your left and right thumbs making navigation between screens a breeze. iPad’s excellent touch technology also means that requiring smaller than normal icons for motors and valves is not a major hindrance.

The iPad InTouch can also have specific widows created just for the purpose of calibration for instance. This offers greater flexibility over the standard operator terminal as the engineer can perform monitoring and adjustment tasks at the equipment source which would be inconvenient if the operator terminal was located out of visual range to the equipment needing to be controlled.

The iPad InTouch does have a smaller surface area for displaying information and this needs to be taken into consideration. Sometimes it is not simply a matter of scaling an existing InTouch window to fit and may require an iPad specific window to be created to suit the smaller screen size. However, all the standard functionality that is usually included in the normal operator terminal can be adapted to the iPad InTouch very easily. This includes alarming screens, product allocation to robot cells, manual and auto control.