On this page:

Systems Integration

The Crossmuller Systems Integration Service provides PLC/SCADA control systems, vision, robotics, MES, ERP integration, IoT and dashboarding solutions, and automated warehousing systems for large and small organisations across multiple industries. Crossmuller is Australia's only Wonderware Endorsed, and has a team experienced in Schneider Electric, Rockwell Automation, Siemens, and Inductive Automation platforms.

On this page:

AUSTRALIA'S ONLY ENDORSED WONDERWARE INTEGRATOR

Wonderware System Integrator Partner

Crossmuller has been a Certified System Integrator since 1997, and in 2011, was invited by Invensys to join a select group of Endorsed System Integrators, making Crossmuller Australia’s first Endorsed System Integrator Partner. The Endorsed SI level is by invitation and only companies with proven technical excellence, high levels of customer service and integrity, coupled with multiple years of certification and project management experience in Wonderware solutions are eligible for consideration.

Inductive Automation's Ignition Core Certification

In 2019, Crossmuller achieved certification on the Core Ignition platform from Inductive Automation. Ignition is a cross-platform SCADA that offers unlimited tags and users per site, combining powerful capability and competitive pricing.

Sepasoft MES Credentials

Built on the Ignition platform, Sepasoft MES offers a comprehensive set of modules to deliver all key manufacturing operation functions. Crossmuller has recently invested in becoming a Sepasoft Credentialed Integrator for their core MES modules. This gives Crossmuller the capability to design and implement a fully functional and tightly integrated plant SCADA and manufacturing execution solution based on the Ignition platform.

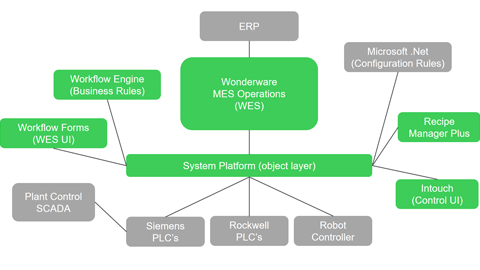

WAREHOUSE EXECUTION SYSTEMS

Crossmuller's flexible, open, and highly integrated Warehouse Execution Systems are built on a Wonderware MES core platform and are capable of working AGVs, Robots, Stacker Cranes or any other warehousing technology.

The Warehouse Integration Challenge

Many manufacturers face a common challenge when it comes to their End of Line systems. Typically, there are line automation PLCs, labelling systems, ASRS/AGV systems and ERP interfaces, which are usually delivered as standalone packages with isolated databases and custom software applications. These fragmented architectures are costly to install, difficult to integrate, poorly supported, result in multiple islands of disconnected master data, and provide little in the way of centralised monitoring and diagnostics, resulting in large meantime to recovery times when issues are encountered.

The Crossmuller Solution

Building on its years of experience in both MES and End of Line automation systems, Crossmuller has developed a fully integrated End of Line Automation and Warehouse Execution System based on Wonderware's MES platform. In comparison with traditional solutions, this offers:

- Seamless integration between End of Line automation and warehousing systems via Wonderware's System Platform and Intouch

- Direct integration with barcode and label printers

-

ERP integration for;

- Customer order picking

- Inventory shipping

- Finished goods receipt

- Stock transfer

-

Standardised interfacing with;

- Stacker cranes

- Area cranes

- AGVs

- Robots

ROBOTICS & VISION

Crossmuller has over 20 years’ experience integrating state-of-the-art 2D and 3D machine vision and ABB and Fanuc robotics handling systems for:

- Defect detection

- Quality inspection

- High accuracy position determination

- Product sorting

- Ultra-high-speed inspection

- Product counting and tracking

- Optical character recognition

- Product measurement

- Image logging

- Vehicle guidance and collision detection

- Weld tracking and guidance

- 3D surface profiling

MANUFACTURING EXECUTION SYSTEMS

Since the early 90s, Crossmuller has been at the forefront of applying software solutions for manufacturing execution and operations management. The team of experienced MES engineers embody the IT/OT convergence with a broad skill set from automation system integration on the plant floor, through to IT infrastructure and ERP system interfacing.

Crossmuller follows a data-driven structured method based on the ISA-S88 and ISA-S95 standards. The organisation’s commitment to developing the skill set of the engineering team is demonstrated by consistent additions to the pool of certified Wonderware MES and System Platform engineers and Crossmuller’s status as a founding member of the Wonderware Model Driven MES competency program

PERFORMANCE

- Equipment availability

- Downtime recording and classification

- OEE

- Data collection and reporting

- Notification and escalation

OPERATIONS

- Work order execution

- ERP system integration

- Production and consumption recording

- Product tracking and genealogy

- Inventory management

- Recipe management

- Labelling

- Barcode scanning

QUALITY

- Paperless quality systems

- Automatic and manual sampling

- Realtime SPC

- ERP and LIMS integration

- Corrective action workflows

SMALL BUSINESS OPERATIONS MANAGEMENT

Save hours per day

Businesses spend 25% of their time managing the paperwork, spreadsheets, pricing, component costs, double entry of information and checking stock levels. More time is spent planning production, batching orders, searching for missing or remade parts, and planning delivery routes and schedules.

Small business manufacturing operations management is an essential tool for small to medium-sized wood working, kitchen and furniture manufacturers to operate their businesses from order entry to delivery in one integrated solution.

Imagine a system where all this is done in the same place!

PLC/SCADA CONTROL SYSTEMS

Crossmuller has a broad range of experience delivering PLC, HMI, SCADA, integrated safety systems and automation networks for process control, batching and discrete manufacturing systems.

Crossmuller specialises in providing integrated machine, line, and plant control systems for Greenfield projects, and successfully planning and executing end of life upgrades and additions to Brownfield systems. Our team of experienced engineers can assist with;

-

Machine, line and plant control system design and implementation using;

- Rockwell PLC5/SLC/Logix, Siemens Step7/TIA, and Beckhoff controllers

- Wonderware System Platform and Intouch, Siemens WinCC, Citect and Rockwell FactoryTalk View / PlantPAX SCADA systems

- Data collection and reporting using ISA-88 and ISA-95 methodologies

- End of Line ERP, automation, warehousing, labelling and scanning integration

-

Functional machine safety to IEC61508;

- Functional Safety Lifecycle including risk assessments, safety requirement specifications, safety system design and validation by TUV certified engineers

- IT infrastructure and automation network design and implementation

- Commissioning